In today’s industrial landscape, the demand for high-quality filtration systems has never been greater. One technology that has revolutionized the industry is the pp melt blown filter machine. This advanced equipment plays a crucial role in producing efficient and reliable filters used across various sectors.

The Functionality of PP Melt Blown Filter Machine

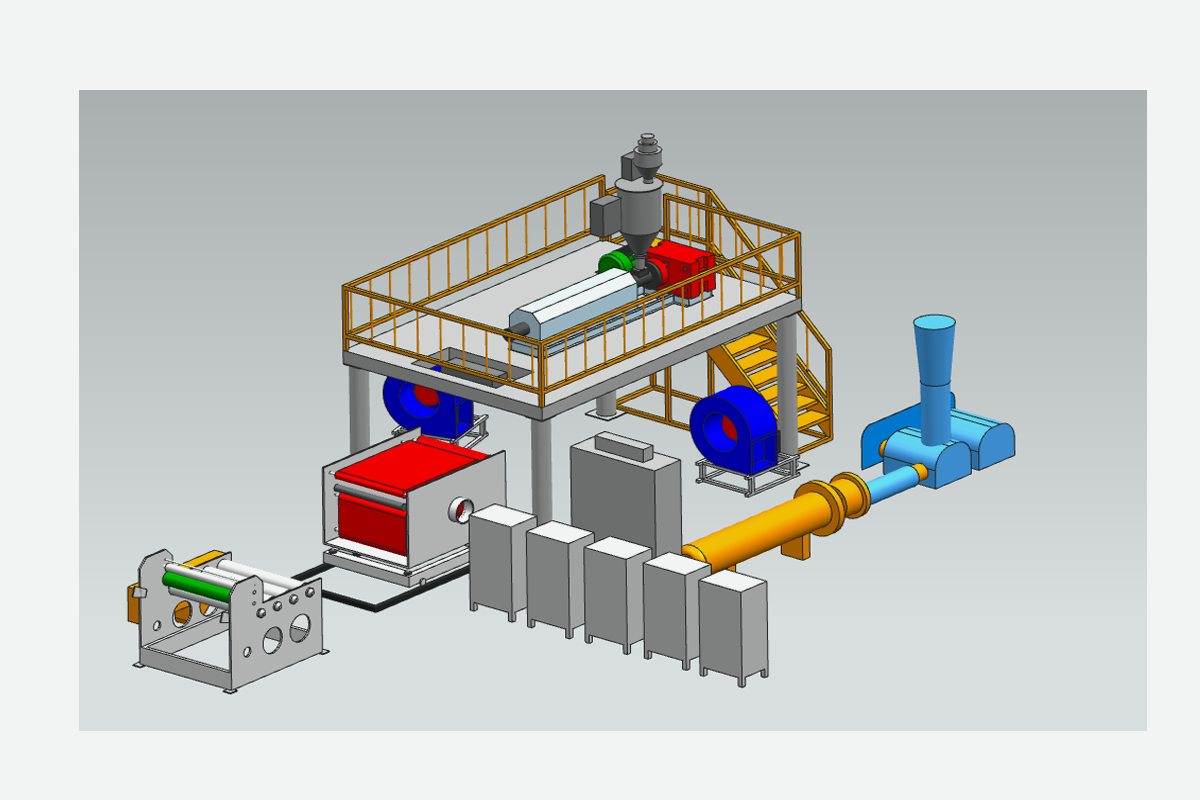

The PP melt blown filter machine utilizes a unique process called melt blowing to create fine fibers from polypropylene materials. These fibers are then layered together to form a dense and uniform matrix, resulting in highly effective filtration media. The machine ensures precise control over parameters such as temperature, pressure, and airflow, guaranteeing consistent quality output.

Hongteng: A Leading Manufacturer of PP Melt Blown Filter Machines

When it comes to top-notch filtration solutions, Hongteng stands out as an industry leader. With years of experience and expertise in manufacturing PP melt blown filter machines, they have gained a reputation for delivering exceptional products worldwide. Their state-of-the-art machinery incorporates cutting-edge technology to meet the stringent requirements of diverse industries.

The Role of Carbon Filter Cartridge Making Machine

In conjunction with the PP melt blown filter machine, carbon filter cartridge making machines play a vital role in enhancing filtration efficiency. These machines enable the production of carbon-impregnated cartridges that effectively remove impurities such as chlorine and volatile organic compounds from water or air streams. By combining these two technologies seamlessly, manufacturers can provide comprehensive filtration solutions.

Conclusion

The utilization of PP melt blown filter machines ensures consistency in B2B quality by producing high-performance filters consistently. With companies like Hongteng leading the way in manufacturing these advanced machines, the industry can rely on reliable and efficient filtration solutions. By incorporating carbon filter cartridge making machines into the process, manufacturers can further enhance their products’ effectiveness. As a result, industries across the globe benefit from improved air and water quality, contributing to a healthier and safer environment.